Overview

Purpose: Mechatronics (24-778) class project

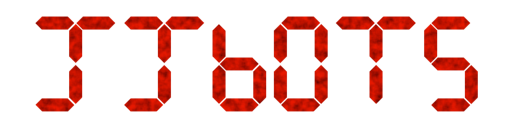

Creator: Team F

My Role: Systems Engineer, Mechanical Design

Form

Drivetrain: Two-wheel differential drive.

Controls: BeagleBone Black

Sensors:

- Webcam with dual mirrors

- 6-DOF IMU

- Optical quadrature encoders

Function

Adhesion: Two neodymium magnets suspended beneath the body provide Rollbot a secure grip on the wall.

Movement: The drivetrain allows the robot to move with precision, even on curved surfaces.

Localization: Direct wheel-encoder connection ensures backlash-free wheel measurements, while the IMU monitors the robot's heading.

Defect Sensing: A single camera points at two angled mirrors, allowing it to see ahead and behind the robot - six cells in total.

Image Processing: The camera's images are processed by OpenCV to accurately and reliably detect 'defects' (discolord squares).

Command & Control: Rollbot is initialized and provides feedback using a UDP socket. Camera images are published by the robot's onboard web server. Advanced control and diagnostics are available over SSH.

Survival: All of the electronics and actuators are protected within an incredibly durable polycarbonate tube with aluminum endcaps.